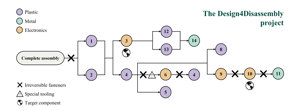

Design for Disassembly

Vision:

Design for disassembly as a key enabler for producers to prepare product and materials for circularity.

Drivers:

- Change of mindset in designing for disassembly

- Develop disassembly methods and design principles as guidelines.

- In the catalogue, solutions for optimizing existing product’s degree of recyclability.

- Develop an experiment for advanced robotic technology for reversed engineering integrating design4disassembly.

The focus on recyclability and reusability of materials have so far been primarily reactive focusing on treatment of waste only – and not going back to optimize design as to prevent waste.

According to EUs Eco-design Directive up to 80 percent of a products environmental impact goes back to the design decision phase. After a product’s end of life, the waste treatment is often at higher cost than the recovery value of the materials. This is often due to mixed materials being melted or glued together. There is an unexplored potential in opportunities for optimization of products recyclability with design for disassembly. Design for Disassembly aligns with circular economy, it meets the extended producer responsibility in a proactive way, by moving from a treatment to a prevention strategy.

Design4Disassembly include developing a disassembly method for accessing product design. This include testing solutions via digital twin design, which are developed to create a mathematical representation of the object in 3D that allow for dimensions, surfaces, and junctions to be accounted for in the design process and important decisions and tests can be conducted on low carbon expense for end-of-life scenarios. With a digital simulation experiment on disassembly, valuable data will be drawn and stored, and materials compositions in the product towards possible updates to the design.

The expected outcome is to provide the companies with a digital twin catalogue to support integration of service, repairability and a higher material recovery of plastic at the product’s end-of life.

Participating partners: University of Southern Denmark, Grundfos Holding A/S, Danfoss Drives and LEGO System A/S.

Project Leader

Lykke Margot Ricard

Mail: lmri@iti.sdu.dk

Henrik Gordon Petersen

Other Plastic Projects