Biocomposites for substituting plastic

Recycling of petrochemical plastic should ideally be an interim remedy while we develop alternatives to plastic.

Aim

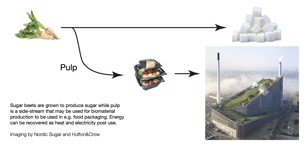

We will exploit agroindustrial waste- and side-streams for lignocellulosic fibers, for the manufacture of cellulose nanofibers and for fermetation of bioplastic monomers; and we will use specialty crops for production of pure amylose. The new agriculture footprint will thus be kept at a minimum.

The biocomposites prepared in the project are relevant to textiles and packaging for example. Food packaging is by far the major usage of plastic for packaging and is targeted specifically in the project. While our materials are iniherently recyclable, meeeting the standards for food contact also in the recycled materials will often not be realistic. Compostability is of importance on a global scale where infrastructure for proper waste handling is often lacking. Composting merely releases the trapped carbondioxide to the atmosphere whereas incineration captures much of the energy while releasing the same amount of carbon dioxide. Carbonification promises a means of turning used packaging material into a carbon store with a half-life measured in decades. Sustainable need not be cyclic.

Unmet needs

- Biobased materials produced by environmenlally friendly processes

- Drop-in technology for using biocomposites in existing packaging materials plants

Some early observations

Cellulose nanofibers and amylose, like most biopolymers, are hydrophilic and while this is good for compostability, it is problematic for strength, barrier properties and interactions between the fibrillar phase and the matrix in a composite. Fiber cells that can be recovered from side-streams from the forestry sector are inexpensive but also 3-4 orders of magnitude bigger than the biopolymers just mentioned. However, the biopolymers can serve as fillers of the interstices between fiber cells; and the fiber cells can be cross-linked in an enzyme mediated process. This greatly reduces hydrophilicity and improves their wet strength as seen in the little bending trial in the image. The thin paper made entirely of fiber cells is impregnated with the aroma compound of tumeric (gurkemeje) and soaked in water. The more slack specimen in A is control while the stiffer B has been enzymatically cross-linked. The aroma compound serves here as a cross-linker.

Read more

About the author

Peter Ulvskov